Fev . 20, 2025 03:01 Back to list

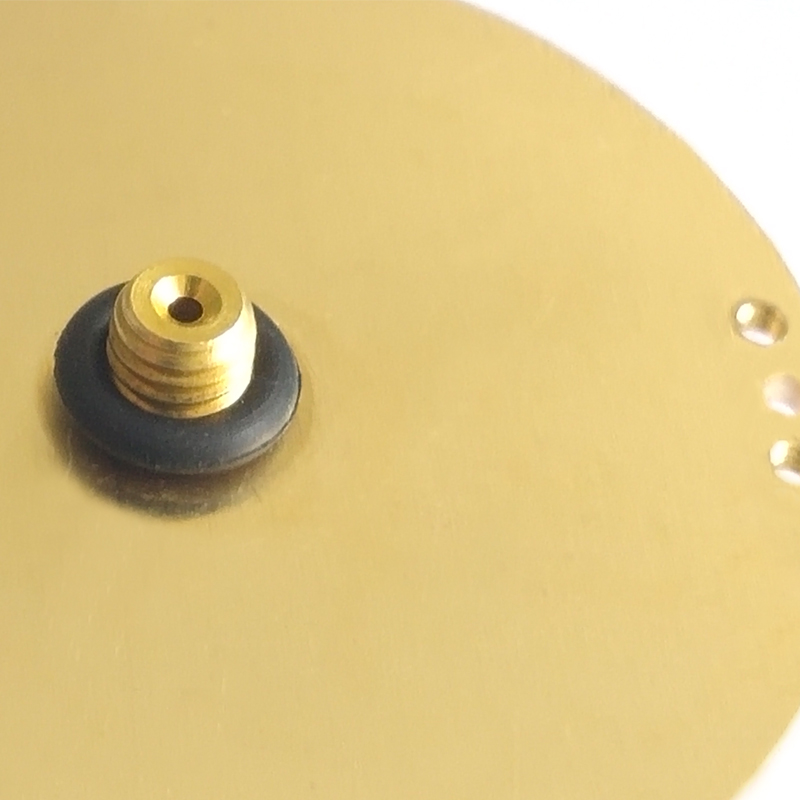

high quality pressure gauge diaphragm type

High quality pressure gauges with diaphragm type are often hailed as the unsung heroes in many industrial applications, offering precision, reliability, and functionality that are unmatched by other types of measurement devices. These specialized instruments play a critical role in monitoring and controlling pressure across various processes, ensuring safety, efficiency, and productivity in a multitude of sectors.

Authoritativeness in the realm of diaphragm pressure gauges is established through compliance with international standards such as ASME, EN, and ISO. Manufacturers that adhere to these standards demonstrate a commitment to quality and safety, gaining the trust of engineers and industry leaders worldwide. These standards ensure that the gauges not only meet performance expectations but also conform to the rigorous demands of different applications. Another crucial aspect of diaphragm pressure gauges is their adaptability. These instruments can be customized with different diaphragm materials, fill fluids, or connection types to suit specific needs. This flexibility is particularly valuable in complex systems where unique process parameters must be accommodated. For instance, in the food industry, where high sanitation is paramount, choosing a gauge with a food-grade diaphragm and hygienic connections is essential. Such customization ensures that the gauges integrate seamlessly into existing systems, enhancing the overall process efficiency. Trustworthiness is further reinforced by the technological advancements integrated into modern diaphragm pressure gauges. With the advent of digital technologies, many high quality gauges now feature smart capabilities such as remote monitoring, data logging, and connectivity with control systems. These advancements allow operators to receive real-time data, facilitating proactive maintenance and immediate response to potential issues. The ability to monitor pressure levels continuously and accurately boosts confidence in system operations and minimizes downtime, which is critical in maintaining productivity and safety. In conclusion, high quality diaphragm pressure gauges are vital components across various industries, offering unparalleled precision, durability, and customization. Their design not only protects against harsh conditions but also aligns with international safety standards, making them a trusted choice for engineers and industry experts. As technology continues to evolve, these gauges are set to become even more integral to the efficient and safe operation of critical systems. For industries that prioritize reliability and accuracy, investing in high quality diaphragm pressure gauges is not just a necessity but a strategic advantage.

Authoritativeness in the realm of diaphragm pressure gauges is established through compliance with international standards such as ASME, EN, and ISO. Manufacturers that adhere to these standards demonstrate a commitment to quality and safety, gaining the trust of engineers and industry leaders worldwide. These standards ensure that the gauges not only meet performance expectations but also conform to the rigorous demands of different applications. Another crucial aspect of diaphragm pressure gauges is their adaptability. These instruments can be customized with different diaphragm materials, fill fluids, or connection types to suit specific needs. This flexibility is particularly valuable in complex systems where unique process parameters must be accommodated. For instance, in the food industry, where high sanitation is paramount, choosing a gauge with a food-grade diaphragm and hygienic connections is essential. Such customization ensures that the gauges integrate seamlessly into existing systems, enhancing the overall process efficiency. Trustworthiness is further reinforced by the technological advancements integrated into modern diaphragm pressure gauges. With the advent of digital technologies, many high quality gauges now feature smart capabilities such as remote monitoring, data logging, and connectivity with control systems. These advancements allow operators to receive real-time data, facilitating proactive maintenance and immediate response to potential issues. The ability to monitor pressure levels continuously and accurately boosts confidence in system operations and minimizes downtime, which is critical in maintaining productivity and safety. In conclusion, high quality diaphragm pressure gauges are vital components across various industries, offering unparalleled precision, durability, and customization. Their design not only protects against harsh conditions but also aligns with international safety standards, making them a trusted choice for engineers and industry experts. As technology continues to evolve, these gauges are set to become even more integral to the efficient and safe operation of critical systems. For industries that prioritize reliability and accuracy, investing in high quality diaphragm pressure gauges is not just a necessity but a strategic advantage.

Share

Latest news

-

Differential Pressure Gauge Kits Precision Tools & Best Pricing

NewsMay.15,2025

-

Hydraulic Differential Pressure Gauge Accurate & Durable Industrial Solutions

NewsMay.15,2025

-

Pressure Gauges for Fire Protection Services Durable Air/Water Rated

NewsMay.15,2025

-

Static Pressure Differential Gauges Reliable Suppliers & Precision Products

NewsMay.14,2025

-

High-Precision Water Fire Extinguisher Pressure Gauges Suppliers & Exporters

NewsMay.14,2025

-

Fire Extinguisher Gauge Pressure Solutions Reliable Water Extinguisher Suppliers

NewsMay.14,2025