Dez . 29, 2024 19:21 Back to list

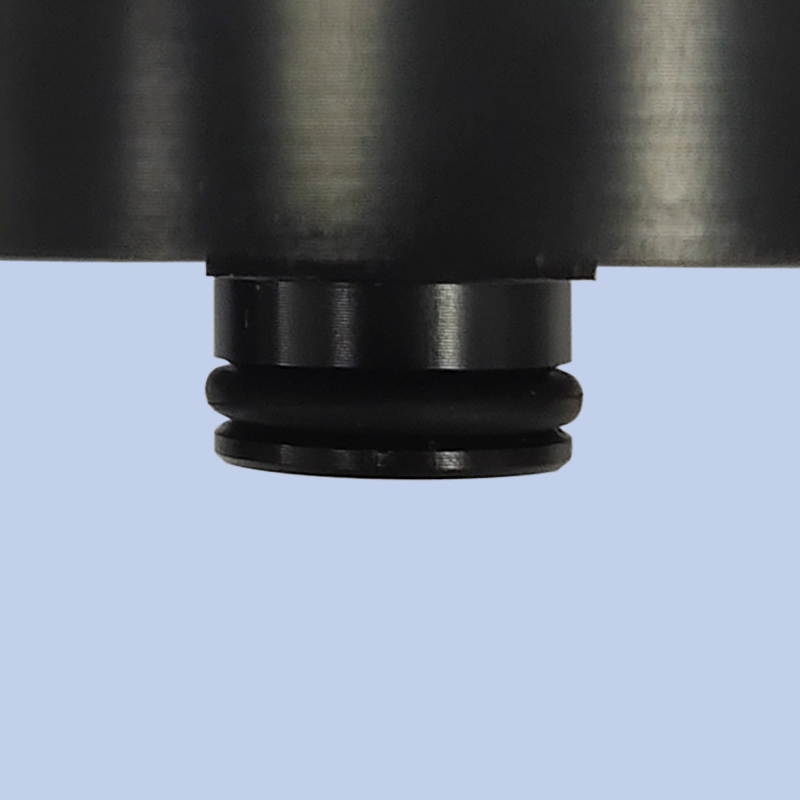

odm differential pressure gauges

Understanding ODM Differential Pressure Gauges

Differential pressure gauges play a crucial role in various industrial applications, providing essential data for monitoring and controlling processes. Among various types of differential pressure gauges available, ODM (Original Design Manufacturer) differential pressure gauges stand out due to their innovative designs and reliable performance. This article delves into the characteristics, applications, and benefits of ODM differential pressure gauges.

What are Differential Pressure Gauges?

A differential pressure gauge measures the difference in pressure between two points in a system, allowing operators to assess flow rates, filter conditions, and equipment efficiency. These instruments can be used across a multitude of sectors, including HVAC, pharmaceuticals, water treatment, and oil and gas. By providing real-time data, differential pressure gauges ensure the smooth operation of processes and help prevent equipment failure.

Features of ODM Differential Pressure Gauges

ODM differential pressure gauges are specifically designed to meet the unique needs of various industries. Some key features include

1. Robust Construction ODM gauges are manufactured using high-quality materials that withstand harsh operating conditions. This durability extends their service life and reduces maintenance costs.

2. High Accuracy Accuracy is critical in pressure measurement. ODM differential pressure gauges are engineered to provide precise readings, ensuring that operators can rely on the data for critical decision-making.

3. Wide Operational Range These gauges typically offer a wide range of measurement capabilities, making them versatile for use in different applications, whether measuring low or high differential pressures.

4. User-Friendly Interface Many ODM gauges feature intuitive displays and controls, allowing for easy installation and operation. Some models even incorporate digital displays for clearer reading and enhanced functionality.

5. Customization Options ODM manufacturers often provide customization options to meet specific customer requirements. This flexibility allows organizations to modify gauge settings, materials, and designs based on their unique applications.

Applications of ODM Differential Pressure Gauges

odm differential pressure gauges

The versatility of ODM differential pressure gauges allows them to be utilized across various industries. Here are a few notable applications

1. HVAC Systems In heating, ventilation, and air conditioning systems, differential pressure gauges monitor airflow and filter conditions, ensuring optimal performance and energy efficiency.

2. Filter Monitoring In industries such as water treatment and pharmaceuticals, these gauges are vital for monitoring the pressure drop across filters. A significant change in differential pressure can indicate the need for maintenance or replacement.

3. Process Control In chemical and petrochemical industries, maintaining precise differential pressure is crucial for process optimization. ODM gauges help monitor reactors, pipelines, and other critical points in the system.

4. Cleanroom Environments In settings that require stringent cleanliness standards, such as laboratories and pharmaceutical manufacturing, differential pressure gauges ensure that pressure differentials are maintained to prevent contamination.

Benefits of Using ODM Differential Pressure Gauges

Implementing ODM differential pressure gauges offers numerous advantages

- Increased Efficiency By monitoring pressure differentials, organizations can optimize their processes, reducing energy consumption and operational costs.

- Improved Safety Accurate pressure monitoring helps identify potential issues before they escalate, enhancing safety within industrial operations.

- Higher Performance Reliability With rigorous quality standards, ODM gauges provide reliable performance, minimizing downtime and increasing productivity.

In conclusion, ODM differential pressure gauges are indispensable tools across various industries, offering robust performance, high accuracy, and adaptability. Their advanced features and beneficial applications make them an excellent choice for organizations seeking to optimize their processes and ensure operational efficiency. As industries continue to evolve, the role of differential pressure measurements will increasingly contribute to enhanced reliability and safety in operational environments.

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025