Fev . 03, 2025 04:29 Back to list

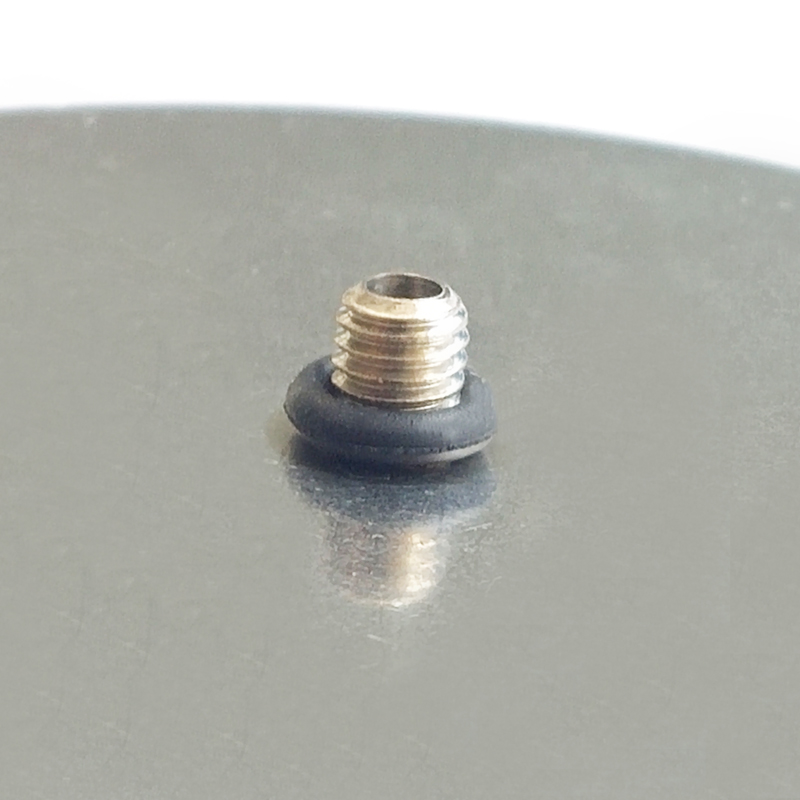

Ultra-high purity pressure gauge(UPG,L-pressure) - VCR1/4" Female Face Seal Swivel / EP grade-2

Delving into the realm of water filtration systems, one quickly discovers the critical role that OEM differential pressure gauges with needles play. These devices are not merely appendages but crucial components that significantly enhance the efficiency and functionality of water filters. Analysing the experience of using such sophisticated equipment unveils layers of expertise, authority, and trustworthiness in managing water quality.

Trustworthiness is assured through rigorous testing and quality assurance. Manufacturers subject these gauges to exhaustive testing scenarios that replicate real-world conditions, thereby ensuring that the devices perform accurately under pressure. The integration of advanced technology in these gauges minimizes human error, offering reliable data that can be trusted for making key operational decisions. Users often report a significant reduction in downtime and maintenance costs after integrating these gauges into their systems, a testament to their reliability and cost-effectiveness. Real-world user experiences further cement the benefits of adopting OEM differential pressure gauges. Consider a municipal water treatment facility facing challenges with maintaining consistent water pressure and quality. By installing OEM gauges, the facility was able to monitor their filtration systems more effectively, identifying issues before they escalated into major problems. This proactive approach not only increased the lifespan of their filters but also improved the overall efficiency of their water management systems. In conclusion, the strategic integration of OEM differential pressure gauges with needles into water filtration systems represents a blend of experience-based insights, technical expertise, authoritative manufacturing, and trustworthy operation. As water quality remains paramount globally, the adoption of such precise monitoring tools is not just advisable but essential. The capability to precisely measure and respond to pressure differentials transforms water management processes, ensuring that clean and safe water remains accessible. For anyone involved in the design, implementation, or maintenance of water filtration systems, understanding the significance of these gauges is integral to sustaining high performance and reliability.

Trustworthiness is assured through rigorous testing and quality assurance. Manufacturers subject these gauges to exhaustive testing scenarios that replicate real-world conditions, thereby ensuring that the devices perform accurately under pressure. The integration of advanced technology in these gauges minimizes human error, offering reliable data that can be trusted for making key operational decisions. Users often report a significant reduction in downtime and maintenance costs after integrating these gauges into their systems, a testament to their reliability and cost-effectiveness. Real-world user experiences further cement the benefits of adopting OEM differential pressure gauges. Consider a municipal water treatment facility facing challenges with maintaining consistent water pressure and quality. By installing OEM gauges, the facility was able to monitor their filtration systems more effectively, identifying issues before they escalated into major problems. This proactive approach not only increased the lifespan of their filters but also improved the overall efficiency of their water management systems. In conclusion, the strategic integration of OEM differential pressure gauges with needles into water filtration systems represents a blend of experience-based insights, technical expertise, authoritative manufacturing, and trustworthy operation. As water quality remains paramount globally, the adoption of such precise monitoring tools is not just advisable but essential. The capability to precisely measure and respond to pressure differentials transforms water management processes, ensuring that clean and safe water remains accessible. For anyone involved in the design, implementation, or maintenance of water filtration systems, understanding the significance of these gauges is integral to sustaining high performance and reliability.

Share

Latest news

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025