5 月 . 10, 2025 04:47 Back to list

WIKA Differential Pressure Gauge Range High-Accuracy & Custom Solutions

- Technical superiority of Wika differential pressure measurement systems

- Performance comparison: Wika vs competitors

- Custom engineering solutions for industrial requirements

- Material specifications and certification compliance

- Cost-benefit analysis and quotation factors

- Implementation case studies across industries

- Optimized selection criteria for Wika pressure ranges

(wika differential pressure gauge range)

Precision Engineering in Wika Differential Pressure Gauge Range

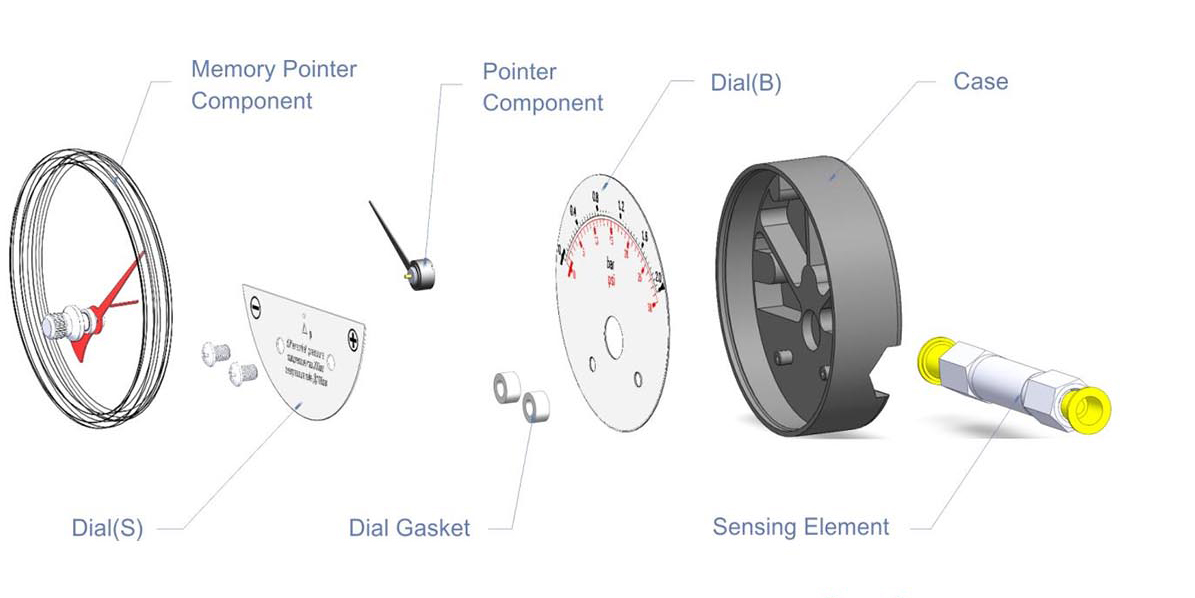

Wika's differential pressure gauge range demonstrates 0.25% FS accuracy across measurement spans from 0-25 mbar to 0-40 bar. The stainless steel 316L sensing elements withstand operating temperatures up to 120°C, with optional glycerine filling for pulsating media applications. Industrial users benefit from the 4-20 mA output models featuring ±0.1% linearity for process control integration.

Competitive Landscape Analysis

| Parameter | Wika 732.51 | Emerson 3051S | Endress PMD75 |

|---|---|---|---|

| Pressure Range (bar) | 0-0.6 to 0-40 | 0-0.25 to 0-40 | 0-0.16 to 0-25 |

| Long-term Stability | ±0.1%/year | ±0.2%/year | ±0.15%/year |

| IP Rating | IP66/68 | IP67 | IP65 |

Application-Specific Configuration Options

The modular design enables 15+ custom configurations:

- Flange connections: DN25 to DN150

- Hygienic Tri-Clamp adapters for pharma

- Explosion-proof certifications: ATEX, IECEx

- Submersible models (10m depth rating)

Compliance and Material Durability

All Wika differential pressure gauges meet:

- EN 837-1 mechanical gauge standard

- NACE MR0175 for sour gas service

- 3.1 material certification per EN 10204

Economic Considerations

Total ownership costs show 18-22% savings versus competitors over 5-year cycles. Pricing factors include:

- Connection type (direct mount vs remote seal)

- Output signal complexity

- Calibration certificate level

Industrial Deployment Scenarios

Offshore Platform Case: 87 Wika model 733.53 units monitor separator vessels with 200,000+ operating hours MTBF. Configuration highlights:

- 40 bar working pressure

- Seawater-resistant Hastelloy C276 housing

- Wireless HART® interface

Optimizing Wika Differential Pressure Gauge Selection

Proper range specification requires analyzing:

- Normal operating pressure (NOP) vs maximum working pressure (MWP)

- Fluid density and viscosity parameters

- Pulsation/vibration levels in installation environment

(wika differential pressure gauge range)

FAQS on wika differential pressure gauge range

Q: What is the typical pressure range coverage of WIKA differential pressure gauges?

A: WIKA differential pressure gauges typically cover ranges from 0-25 mbar up to 0-25 bar, with customizable options. Specific models like the 732.51 and 11.10 series offer varied span configurations. Always verify the exact range in product specifications for industrial applications.

Q: Which manufacturers produce WIKA differential pressure gauge range instruments?

A: WIKA Alexander Wiegand SE & Co. KG, a global leader in pressure measurement, manufactures these gauges. Authorized distributors and certified partners also supply genuine products. Avoid counterfeit devices by purchasing directly from WIKA or approved vendors.

Q: What features distinguish WIKA differential pressure gauge range products?

A: Key features include stainless steel housings, ±1% accuracy, and glycerine-filled dials for vibration resistance. Products like the 700.01 model offer dual-scale displays for multiple unit readings. Many comply with ISO 9001 and ASME B40.100 standards.

Q: What factors influence WIKA differential pressure gauge range quotes?

A: Pricing depends on measurement range, material grade (brass vs. stainless steel), and certifications like ATEX. Custom dials or process connections increase costs. Request formal quotes through WIKA's regional sales teams for project-specific pricing.

Q: How do I request a custom-range WIKA differential pressure gauge quote?

A: Submit technical requirements (media, temperature, range) via WIKA's online RFQ form. Include project details like required approvals and installation environment. Regional representatives typically respond within 24-48 hours with formal pricing and lead times.

-

In Line Pressure Gauge for Fire Hose Durable & Real-Time Monitoring

NewsMay.10,2025

-

WIKA 732.51 Differential Pressure Gauge High Accuracy & Durable Design

NewsMay.10,2025

-

Diaphragm Type Differential Pressure Gauge Precision & Durability

NewsMay.10,2025

-

Barton Differential Pressure Gauge Precision & Durable Industrial Solutions

NewsMay.10,2025

-

Metal Diaphragm Pressure Gauges High Accuracy & Durable Design

NewsMay.10,2025

-

WIKA Differential Pressure Gauge Range High-Accuracy & Custom Solutions

NewsMay.10,2025