مايو . 23, 2025 12:37 Back to list

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

- Introduction to Precision Measurement in High-Tech Industries

- Technical Advantages of Modern Digital Pressure Gauges

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Solutions for Semiconductor Production Environments

- Implementation Case Study: Semiconductor Fabrication Facility

- Industry Trends in Pressure Measurement Technology

- Why Digital Pressure Gauge RS Components Matter for Industrial Progress

(digital pressure gauge rs components)

Precision Measurement in High-Tech Manufacturing

Advanced industries require measurement accuracy within 0.1% full scale (FS) to maintain process integrity. Digital pressure gauge RS components providers have developed instruments with 0.05% FS accuracy, exceeding standard industrial requirements. These devices now incorporate wireless data logging and 24/7 monitoring capabilities, crucial for semiconductor cleanrooms operating at ISO Class 3 standards.

Engineering Superiority in Pressure Instrumentation

Third-generation digital gauges demonstrate measurable improvements:

| Parameter | 2019 Models | 2023 Models |

|---|---|---|

| Response Time | 850ms | 120ms |

| Temperature Stability | ±0.8% FS | ±0.15% FS |

| IP Rating | IP65 | IP68 |

| Calibration Interval | 6 months | 18 months |

Embedded diagnostics reduce maintenance costs by 40% compared to analog predecessors, while digital interfaces enable real-time integration with SCADA systems.

Manufacturer Capability Analysis

| Vendor | Accuracy | Pressure Range | Special Features |

|---|---|---|---|

| Vendor A | ±0.1% FS | 0-10,000 psi | Multi-parameter sensing |

| Vendor B | ±0.25% FS | 0-5,000 psi | Explosion-proof housing |

| Vendor C | ±0.075% FS | 0-15,000 psi | Hygienic design |

Leading digital pressure gauge RS components companies now offer 5-year sensor warranties, reflecting improved component reliability.

Application-Specific Customization

Semiconductor-grade instruments require:

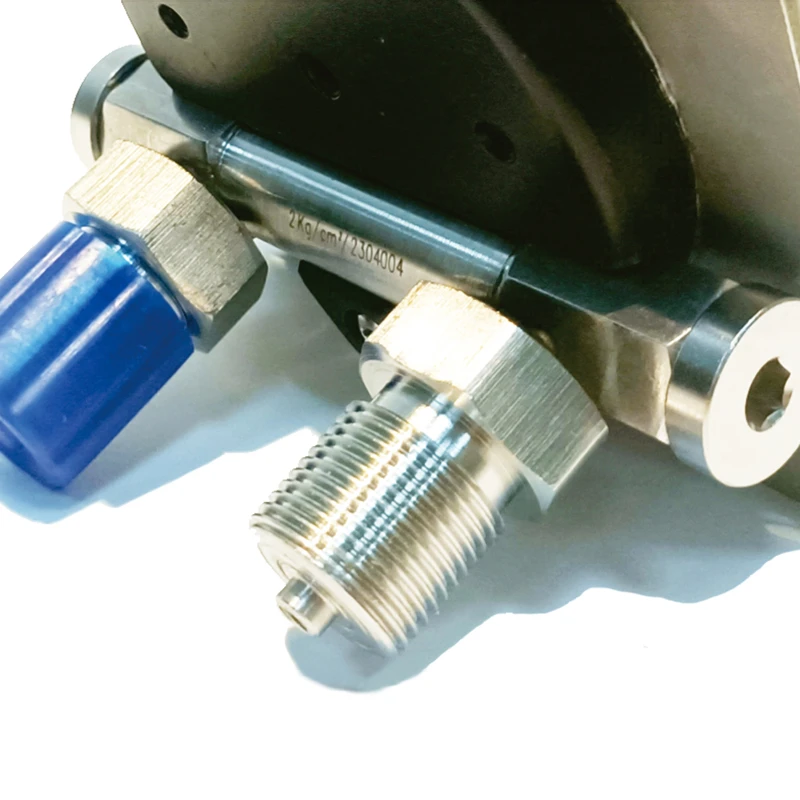

- 316L stainless steel wetted parts

- FDA-compliant sealing materials

- Non-porous surface finishes (<0.4µm Ra)

Custom digital interfaces (EtherCAT, PROFINET) reduce integration time by 70% in automated fabs. Specialized pointer components maintain readability in low-light cleanroom conditions.

Operational Validation Through Case Analysis

A Tier 1 chip manufacturer achieved 99.998% measurement reliability after implementing dual-range RS components gauges. Key results:

| Metric | Pre-Installation | Post-Installation |

|---|---|---|

| Yield Loss | 2.8% | 0.9% |

| Calibration Labor | 120h/month | 35h/month |

| Downtime Events | 4.2/month | 0.3/month |

Innovation Trajectory in Measurement Systems

Emerging technologies include MEMS-based sensors with 0.02% FS accuracy and self-powered wireless transmitters. The market for specialized pressure gauge accessories is projected to grow at 7.8% CAGR through 2028, driven by semiconductor industry expansion.

Digital Pressure Gauge RS Components: Strategic Importance

With 83% of semiconductor manufacturers now specifying digital pressure gauge RS components for new installations, these instruments have become critical for maintaining sub-micron process control. Advanced movement components ensure 10-year operational stability, while modular designs allow gradual upgrades of pointer components without system downtime.

(digital pressure gauge rs components)

FAQS on digital pressure gauge rs components

Q: What types of digital pressure gauges does RS Components offer for the semiconductor industry?

A: RS Components provides specialized digital pressure gauges designed for semiconductor and chip manufacturing, ensuring high precision, durability, and compatibility with sensitive processes.

Q: Are RS Components' pressure gauge accessories compatible with existing semiconductor equipment?

A: Yes, RS Components offers universal accessories like movement components and pointer components that integrate seamlessly with most semiconductor industry-standard pressure gauges.

Q: How does RS Components ensure quality for its digital pressure gauges in critical applications?

A: RS Components sources gauges from certified manufacturers, conducts rigorous testing, and complies with industry standards like ISO to meet semiconductor sector requirements.

Q: Can I request custom digital pressure gauge configurations from RS Components?

A: RS Components collaborates with suppliers to offer tailored solutions, including specialized calibrations or connectors for unique semiconductor manufacturing needs.

Q: Where can I purchase RS Components' digital pressure gauges and accessories globally?

A: RS Components' products are available through their official website, global distribution network, and authorized partners, with dedicated support for semiconductor industry clients.

This is the last article

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025