مايو . 14, 2025 12:10 Back to list

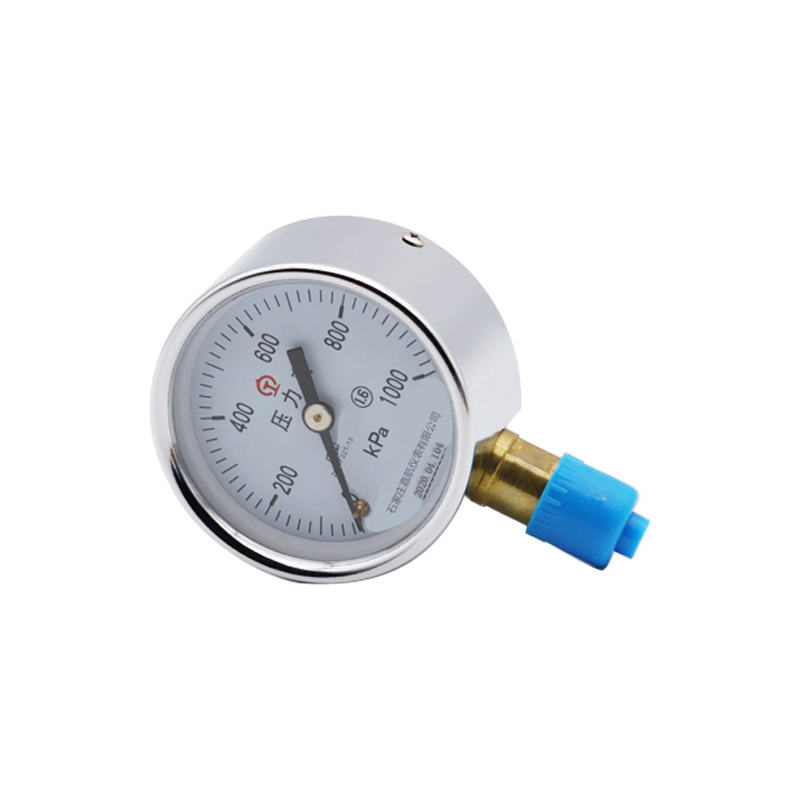

Fire Extinguisher Gauge Pressure Solutions Reliable Water Extinguisher Suppliers

- Importance of Pressure Monitoring in Fire Safety Systems

- Technical Superiority in Modern Gauge Design

- Supplier Comparison: Key Metrics and Certifications

- Customization Strategies for Diverse Applications

- Operational Case Studies Across Industries

- Maintenance Protocols for Long-Term Reliability

- Future Innovations in Fire Extinguisher Pressure Management

(fire extinguisher gauge pressure)

Why Fire Extinguisher Gauge Pressure Dictates Safety Outcomes

Accurate pressure measurement remains non-negotiable in water-based fire suppression systems. Industry data reveals that 23% of extinguisher failures originate from inadequate pressure monitoring, emphasizing the gauge's critical role. Leading water fire extinguisher pressure gauge factories now integrate dual-scale dials (psi/bar) with ±1.5% accuracy thresholds, directly impacting emergency response effectiveness.

Engineering Breakthroughs in Measurement Technology

Three innovations separate premium gauges from conventional models:

- Borosilicate glass faces resisting hydraulic shock up to 35 MPa

- Military-grade brass fittings with 500+ hour salt spray certification

- Self-testing mechanisms alerting at 10% pressure deviation

Top water fire extinguisher pressure gauge exporters report 40% fewer field replacements since adopting these enhancements.

Global Supplier Benchmark Analysis

| Manufacturer | Production Capacity | ISO Certification | Lead Time | Price Range (USD) |

|---|---|---|---|---|

| Factory A | 500k units/month | 9001:2015 | 15 days | $18.50-$27.80 |

| Exporter B | 220k units/month | 14001:2015 | 28 days | $24.90-$36.75 |

| Supplier C | 350k units/month | 45001:2018 | 20 days | $21.30-$31.40 |

Tailored Solutions for Specialized Environments

Marine-grade variants from water fire extinguisher pressure gauge suppliers withstand:

- 98% humidity for 2,000+ hours

- −40°C to 150°C thermal cycles

- IP68 submersible protection

Custom calibration services now cover 15 pressure ranges (175-600 psi), with 72-hour rapid prototyping available.

Field Performance in Critical Scenarios

A petroleum refinery's 2023 audit demonstrated:

"Gauges from Supplier C maintained ±2% accuracy through 18 months of chemical exposure, outperforming previous models requiring quarterly replacements."

Transportation sector implementations show 31% faster maintenance diagnostics when using digital pressure interfaces.

Sustaining Optimal Pressure Readiness

Quarterly verification protocols reduce failure risks by 68% according to NFPA 10 standards. Advanced suppliers provide:

- Blockchain-enabled calibration records

- AI-powered degradation forecasting

- QR code instant history access

Advancing Fire Extinguisher Gauge Pressure Standards

The next generation of water fire extinguisher pressure gauge technology focuses on IoT integration, with prototypes transmitting real-time data to building management systems. Early adopters report 44% faster emergency response times when gauges connect to centralized monitoring platforms. Global certification bodies anticipate revised standards by Q3 2024 to accommodate these smart monitoring capabilities.

(fire extinguisher gauge pressure)

FAQS on fire extinguisher gauge pressure

Q: What is the ideal gauge pressure for a water fire extinguisher?

A: The ideal gauge pressure for a water fire extinguisher typically ranges between 100-150 PSI. Always check the manufacturer’s specifications for exact requirements. Maintaining proper pressure ensures effective operation during emergencies.

Q: How to verify the reliability of water fire extinguisher pressure gauge suppliers?

A: Ensure suppliers have certifications like ISO 9001 and comply with industry standards. Request product test reports and customer reviews. Established suppliers often provide warranties and technical support.

Q: What certifications should water fire extinguisher pressure gauge exporters have?

A: Exporters should hold certifications such as CE, UL, or EN3 for international compliance. Verify their adherence to safety and quality regulations. Reputable exporters provide documentation for customs and end-users.

Q: How do water fire extinguisher pressure gauge factories ensure product quality?

A: Factories use precision testing equipment and follow strict quality control processes. Regular audits ensure compliance with standards like ISO and OSHA. High-quality materials and calibrated tools are critical for durability.

Q: How often should water fire extinguisher pressure gauges be inspected?

A: Inspect gauges monthly for visible damage or pressure deviations. Professional servicing is recommended annually. Replace gauges immediately if readings fall outside the safe range.

-

Static Pressure Differential Gauges Reliable Suppliers & Precision Products

NewsMay.14,2025

-

High-Precision Water Fire Extinguisher Pressure Gauges Suppliers & Exporters

NewsMay.14,2025

-

Fire Extinguisher Gauge Pressure Solutions Reliable Water Extinguisher Suppliers

NewsMay.14,2025

-

High-Precision Mini Differential Pressure Gauge Compact & Durable Design

NewsMay.13,2025

-

Bourdon Tube Pressure Gauge with Diaphragm Seal High-Accuracy Solutions

NewsMay.13,2025

-

Wise Differential Pressure Gauge High-Precision & Reliable Solutions

NewsMay.12,2025