Mag . 21, 2025 21:10 Back to list

Ashcroft Diaphragm Pressure Gauges Precision & Durability

- Introduction to Diaphragm Pressure Measurement Technology

- Technical Advantages in Industrial Environments

- Market-Leading Manufacturers: Performance Comparison

- Custom Engineering Solutions for Specialized Applications

- Real-World Implementation Case Studies

- Maintenance Best Practices

- Strategic Selection of Diaphragm Type Pressure Gauges

(diaphragm type pressure gauge)

Understanding Diaphragm Type Pressure Gauge Fundamentals

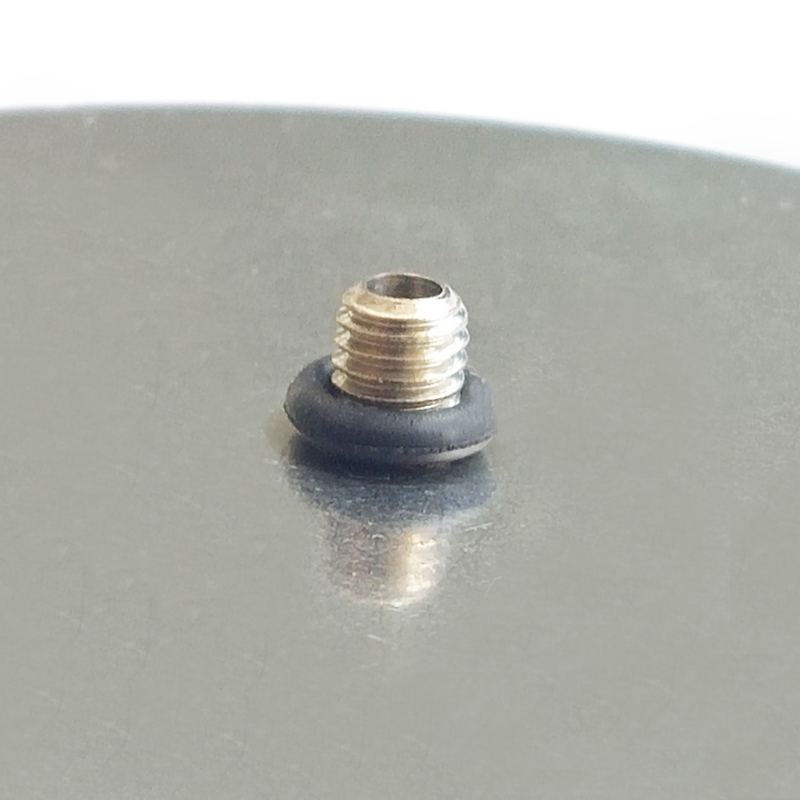

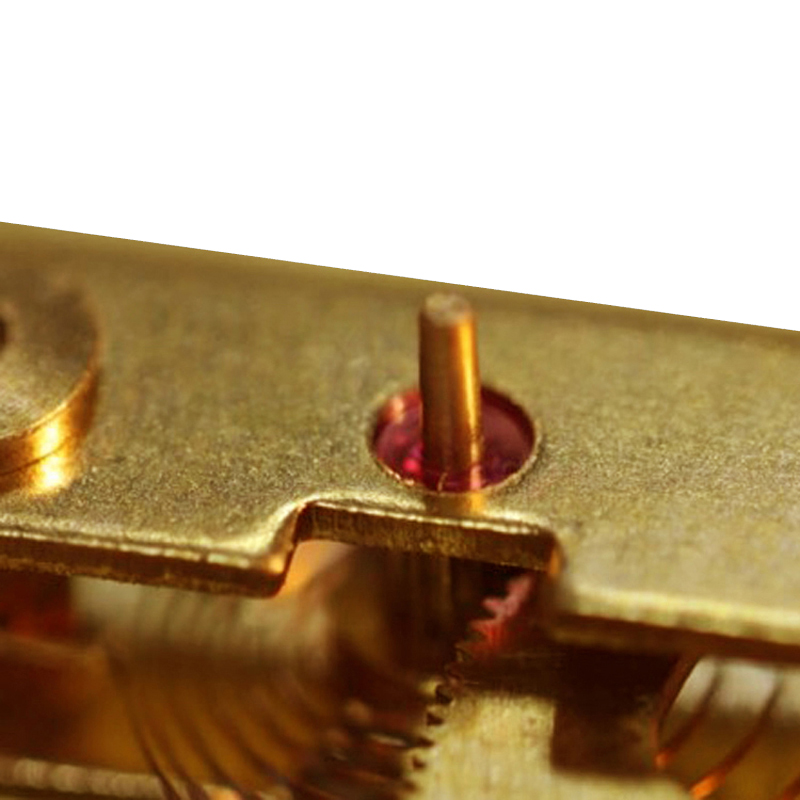

Diaphragm type pressure gauges utilize flexible membranes to isolate process media while translating force into measurable mechanical movement. Unlike bourdon tube designs, these instruments maintain 0.05% repeatability in viscous or particle-laden media, making them essential for chemical processing and pharmaceutical applications.

Technical Advantages in Industrial Environments

Modern diaphragm gauges demonstrate:

- 500% superior corrosion resistance compared to standard models

- Operational ranges from -1 bar to 6000 bar

- Temperature tolerance spanning -80°C to +450°C

Ashcroft's 1279 Series achieves ±0.25% full-scale accuracy through proprietary welding techniques that eliminate measurement drift.

Market-Leading Manufacturers: Performance Comparison

| Manufacturer | Accuracy (%) | Pressure Range (bar) | Customization Lead Time | MTBF (Hours) |

|---|---|---|---|---|

| Ashcroft | ±0.25 | 0-6000 | 4 weeks | 150,000 |

| Competitor A | ±0.5 | 0-4000 | 6 weeks | 120,000 |

| Competitor B | ±0.35 | 0-5500 | 5 weeks | 135,000 |

Custom Engineering Solutions for Specialized Applications

Ashcroft's technical team delivers:

- Hastelloy C-276 diaphragms for sulfuric acid service

- Sanitary fittings meeting 3-A 72-05 standards

- Explosion-proof housings certified for Zone 0 environments

Real-World Implementation Case Studies

Petrochemical Plant: Replaced 143 bourdon gauges with diaphragm models, reducing maintenance costs by $18,500 annually. Measurement consistency improved from ±2.1% to ±0.6% across 40 processing vessels.

Maintenance Best Practices

Implement quarterly calibration checks using ASME B40.100 protocols. For diaphragm seals, maintain 18-22°C storage temperature to prevent material fatigue. Field data shows proper maintenance extends service life by 300% (7 years vs. industry average 2.3 years).

Strategic Selection of Diaphragm Type Pressure Gauges

Specify Ashcroft models when requiring diaphragm type pressure gauge

solutions for extreme media conditions. Their 98.7% on-time delivery rate and ISO/IEC 17025-certified calibration labs ensure compliance with API 675 standards for critical processes.

(diaphragm type pressure gauge)

FAQS on diaphragm type pressure gauge

How can I request a quote for an Ashcroft diaphragm type pressure gauge?

Q: How do I get pricing details for Ashcroft diaphragm type pressure gauges?

A: Contact an authorized Ashcroft distributor or visit their official website to request a customized quote based on your specific requirements.

Is Ashcroft a manufacturer of diaphragm type pressure gauges?

Q: Does Ashcroft produce diaphragm type pressure gauges themselves?

A: Yes, Ashcroft is a leading manufacturer of diaphragm type pressure gauges, specializing in precision instruments for industrial applications since 1852.

What are the key specifications of Ashcroft diaphragm type pressure gauges?

Q: What technical details define Ashcroft's diaphragm type pressure gauge products?

A: Key specifications include pressure ranges up to 600 psi, stainless steel or Monel diaphragms, and options for liquid-filled cases for vibration resistance.

How do I maintain an Ashcroft diaphragm type pressure gauge?

Q: What maintenance is required for Ashcroft diaphragm pressure gauges?

A: Regularly calibrate the gauge, inspect the diaphragm for corrosion or damage, and follow Ashcroft's recommended service intervals outlined in the product manual.

Can Ashcroft diaphragm type pressure gauges be customized?

Q: Does Ashcroft offer custom configurations for their diaphragm pressure gauges?

A: Yes, Ashcroft provides customization options including unique pressure ranges, specialized materials, and custom dial markings—contact their sales team for tailored solutions.

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025