Dic . 21, 2024 06:05 Back to list

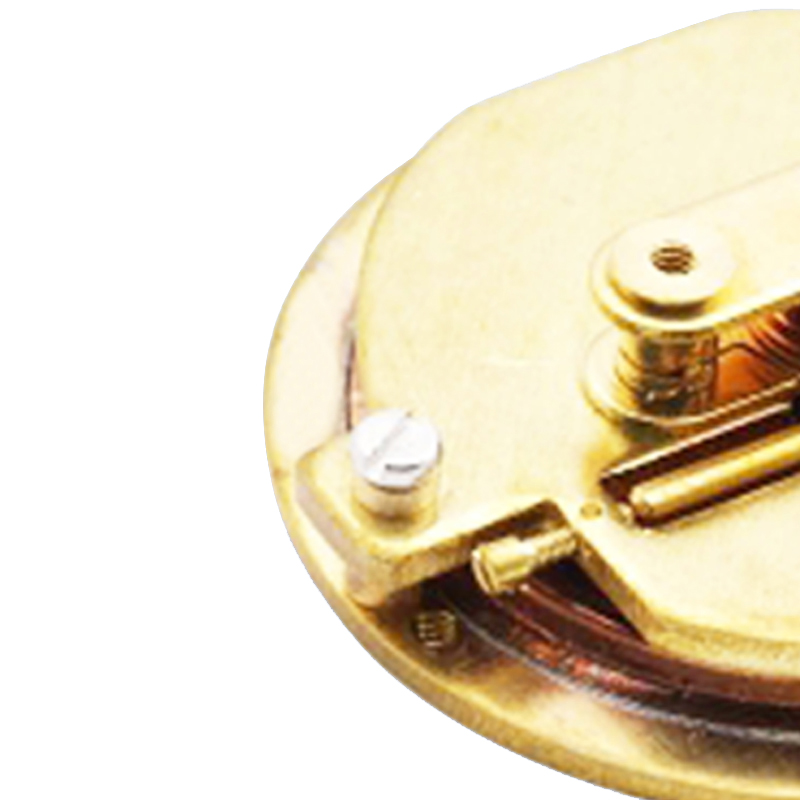

differential pressure gauge assembly

Understanding Differential Pressure Gauge Assemblies

In various industrial applications, the measurement of pressure is crucial for ensuring the safety, efficiency, and functionality of systems. Among the myriad of tools used for measuring pressure, differential pressure gauge assemblies stand out as critical instruments that provide insights into the working conditions of different systems. This article aims to explain what differential pressure gauge assemblies are, how they operate, their applications, and some best practices for their use.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device designed to measure the difference in pressure between two points in a system. Unlike standard pressure gauges that measure absolute or gauge pressure, differential pressure gauges offer a unique advantage by providing a comparative measurement. This is particularly beneficial in applications where pressure drop across a system element, such as filters, hydraulic systems, or tanks, is essential for operational monitoring.

How Differential Pressure Gauge Assemblies Work

The fundamental operating principle of a differential pressure gauge involves two pressure inputs. These inputs correspond to two separate points where pressure is to be measured. The gauge utilizes a diaphragm or a similar sensing element that deforms in response to the pressure differential. As the pressure at one port increases (or decreases), the diaphragm bends, and this movement is translated into a readable value on the gauge face.

The output is typically represented in various units, such as psi (pounds per square inch), bar, or kilopascals. Some advanced differential pressure gauges may interface with digital systems, allowing for remote monitoring and integration with process control systems.

Applications of Differential Pressure Gauge Assemblies

Differential pressure gauge assemblies are versatile tools used across multiple industries and applications. Here are some noteworthy examples

1. HVAC Systems In heating, ventilation, and air conditioning systems, differential pressure gauges monitor airflow through filters. A drop in pressure indicates filter blockage, which helps maintain efficiency and indoor air quality.

2. Process Industry In chemical processing plants, these gauges are essential for ensuring proper flow rates through pipelines and equipment, preventing potential overpressure situations and optimizing process efficiency.

differential pressure gauge assembly

4. Hydraulic Systems They help in assessing the performance and efficiency of hydraulic circuits by monitoring pressure drops across pumps and valves, ensuring that machinery operates within specified parameters.

5. Oil and Gas In this sector, they provide crucial data regarding pressure differences across separators, filters, and flow lines, contributing to safe and efficient operations.

Best Practices for Using Differential Pressure Gauge Assemblies

To achieve optimal performance and extend the lifespan of differential pressure gauges, consider the following best practices

1. Proper Installation Ensure that the gauge is installed in accordance with the manufacturer's specifications. This includes correct orientation and securing of connections to prevent leaks.

2. Regular Calibration Over time, gauges can become less accurate due to wear and tear. Regular calibration and maintenance are essential for maintaining precise measurements.

3. Environmental Considerations Protect gauges from extreme temperatures, vibrations, and corrosive substances, as these factors can affect their operation.

4. Selection of Materials Choose a gauge that is compatible with the fluids being measured. The materials in contact with the fluid can significantly influence the gauge's durability and performance.

5. Monitoring and Data Logging Where applicable, integrate differential pressure gauges with monitoring systems to collect and analyze data over time. This promotes proactive maintenance and helps in decision-making processes.

Conclusion

Differential pressure gauge assemblies are vital instruments utilized in various sectors to measure pressure differences across systems. By understanding their operation, applications, and maintenance practices, industries can ensure optimal performance, safety, and efficiency in their operations. As technology continues to evolve, these gauges are likely to become even more integral to process monitoring and control, enhancing the capabilities of industrial systems worldwide.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025