Ott . 22, 2024 13:37 Back to list

OEM RS Components Pressure Measurement Tools and Applications for Accurate Readings

Understanding OEM Pressure Gauges A Focus on RS Components

Pressure gauges are vital instruments in a wide array of industries, providing essential measurements that ensure systems operate within their intended parameters. Among the various suppliers in the market, RS Components stands out for its extensive range of Original Equipment Manufacturer (OEM) pressure gauges. This article explores the significance of OEM pressure gauges, the offerings from RS Components, and factors to consider when selecting the right gauge for your needs.

What Are OEM Pressure Gauges?

OEM pressure gauges are specially designed for integration into the machinery or systems of original equipment manufacturers. They are built to meet specific specifications and requirements dictated by the manufacturer's applications. Unlike standard gauges which may be uniform in design and function, OEM gauges are tailored for particular uses, providing enhanced accuracy, reliability, and durability.

These gauges are commonly found in various sectors, including automotive, HVAC, marine, and industrial machinery. The precision they offer is crucial for safety and efficiency, as many systems rely on accurate pressure readings to function correctly.

Why Choose RS Components for OEM Pressure Gauges?

RS Components is a well-known distributor of electronic, electrical, and industrial components. Their commitment to quality and an extensive catalog of products make them a go-to source for OEM pressure gauges.

1. Diverse Product Range RS Components offers a wide array of pressure gauges, including analog and digital options, available in various configurations such as differential gauges, absolute gauges, and compound gauges. This extensive range ensures that customers can find the right tool for their unique applications.

2. Quality Assurance One of the significant advantages of sourcing OEM pressure gauges from RS Components is the guarantee of quality. RS Components collaborates with reliable manufacturers that adhere to high manufacturing standards, ensuring that every product is tested for performance and reliability.

3. Ease of Access The RS Components website provides an intuitive platform for browsing and purchasing. Users can easily filter products based on specific criteria such as pressure range, accuracy, and connection type, making it simple to find the right gauge for their applications.

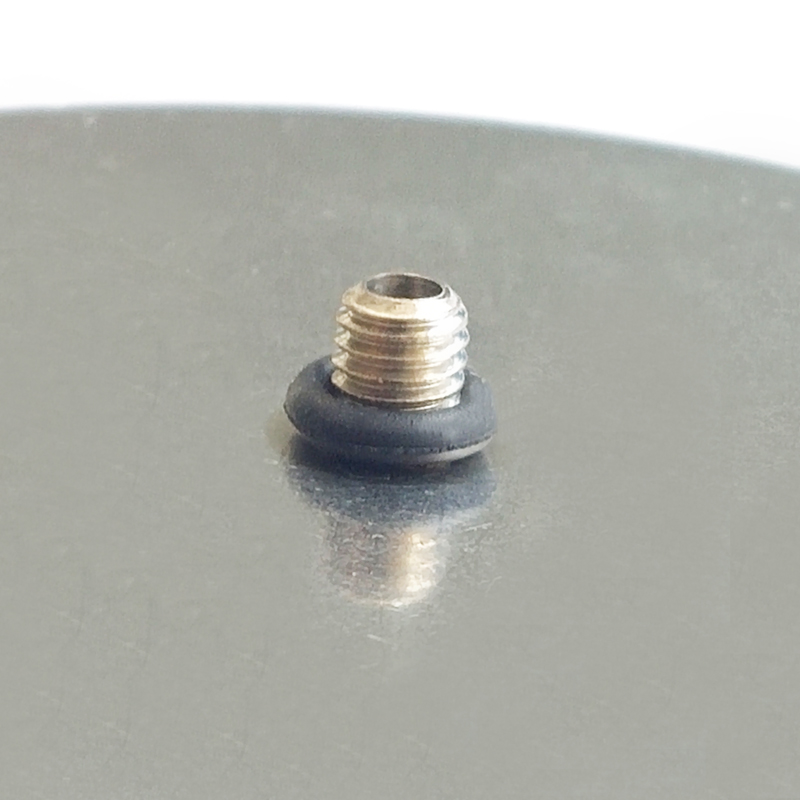

oem rs components pressure gauge

4. Expert Guidance For customers unsure about which product to choose, RS Components offers technical support and resources. Their knowledgeable staff can assist in selecting the best gauge based on application needs, ensuring that customers make informed decisions.

Factors to Consider When Selecting OEM Pressure Gauges

When it comes to choosing the right pressure gauge for your OEM application, several factors should be taken into account

1. Pressure Range It’s critical to select a gauge that can accurately measure the pressure levels expected in your system. Oversized or undersized gauges can lead to inaccurate readings and potentially compromise system integrity.

2. Accuracy The precision of a pressure gauge can vary greatly, often expressed as a percentage of full scale. Ensure you select a gauge that meets the accuracy requirements for your specific application.

3. Environmental Resistance Depending on the application, the pressure gauge may be exposed to extreme temperatures, humidity, or corrosive atmospheres. Choosing a gauge rated for such conditions can enhance its longevity and effectiveness.

4. Connection Types Different systems utilize various connection types. Ensure that the gauge you select is compatible with your existing equipment to avoid installation issues.

5. Calibration and Maintenance Consider whether the pressure gauge requires frequent calibration or maintenance. Some high-precision applications may necessitate regular recalibration to ensure ongoing accuracy.

Conclusion

OEM pressure gauges play a pivotal role in ensuring the safe and efficient operation of equipment across numerous industries. With a comprehensive product range, commitment to quality, and knowledgeable support staff, RS Components is an excellent choice for sourcing these essential instruments. By carefully considering factors such as pressure range, accuracy, environmental conditions, and maintenance needs, users can select the appropriate pressure gauge to meet their specific requirements, ultimately contributing to improved performance and safety within their operations.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025