يناير . 17, 2025 04:56 Back to list

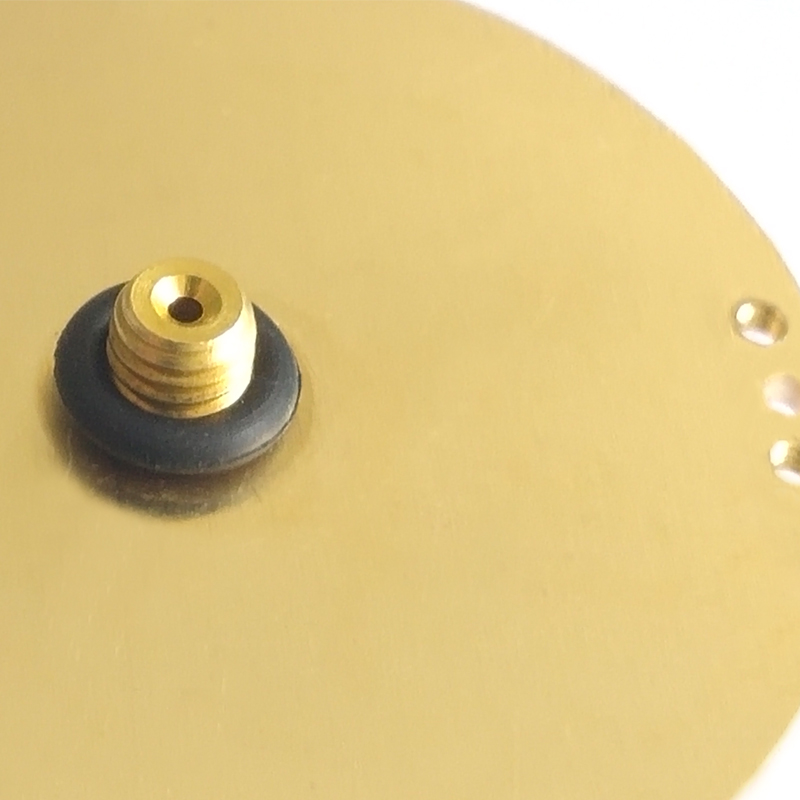

Differential Pressure Gauge-Magnetic piston typeYCC-80.01(851.1)

In the world of industrial measurement, choosing the right instrumentation is paramount to ensuring safety, efficiency, and reliability. Among the myriad of devices available, the differential pressure gauge with a diaphragm seal stands out as a critical tool, especially in harsh environments and processes where accurate pressure measurement is indispensable. This article delves into the intricate details of differential pressure gauges with diaphragm seals, highlighting their design, applications, and advantages, based on a wealth of professional expertise and real-world experience.

From a technical standpoint, expertise in manufacturing and calibrating these gauges is paramount. The manufacturer must ensure that the diaphragm seal does not compromise the accuracy of the pressure readings. This involves meticulous assembly and rigorous testing under simulated operational conditions. Expertise is also required in selecting the appropriate fill fluid for the diaphragm seal, which ensures that the pressure is accurately transmitted to the gauge under varied temperature conditions. A common choice is silicone oil, but the selection can vary based on environmental considerations and process compatibility. Authoritative organizations, such as the American Society of Mechanical Engineers (ASME), provide guidelines and standards which govern the use of diaphragm seals with differential pressure gauges, lending credibility to their application and ensuring their effectiveness under tested conditions. Compliance with these standards assures users that the instruments are reliable and can be trusted to deliver accurate readings in critical scenarios. Trustworthiness in this context is twofold it relates to both the reliability of the instrument itself and the trust in the information it provides. Differential pressure gauges with diaphragm seals have proven their reliability time and again due to their robust construction and adaptability to hostile environments. When maintenance and downtime translate directly to financial loss, industries worldwide rely on these devices for dependability and confidence in continuous operations. In conclusion, differential pressure gauges with diaphragm seals are a testament to the crucial intersection of engineering expertise and practical application. Their role in safeguarding processes across varied industries cannot be overstated, equipping professionals with not just a tool, but a robust solution to their pressure measurement needs. By leveraging cutting-edge design, superior materials, and rigorous testing, these instruments assure precise and reliable measurement, embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness at every level of their application.

From a technical standpoint, expertise in manufacturing and calibrating these gauges is paramount. The manufacturer must ensure that the diaphragm seal does not compromise the accuracy of the pressure readings. This involves meticulous assembly and rigorous testing under simulated operational conditions. Expertise is also required in selecting the appropriate fill fluid for the diaphragm seal, which ensures that the pressure is accurately transmitted to the gauge under varied temperature conditions. A common choice is silicone oil, but the selection can vary based on environmental considerations and process compatibility. Authoritative organizations, such as the American Society of Mechanical Engineers (ASME), provide guidelines and standards which govern the use of diaphragm seals with differential pressure gauges, lending credibility to their application and ensuring their effectiveness under tested conditions. Compliance with these standards assures users that the instruments are reliable and can be trusted to deliver accurate readings in critical scenarios. Trustworthiness in this context is twofold it relates to both the reliability of the instrument itself and the trust in the information it provides. Differential pressure gauges with diaphragm seals have proven their reliability time and again due to their robust construction and adaptability to hostile environments. When maintenance and downtime translate directly to financial loss, industries worldwide rely on these devices for dependability and confidence in continuous operations. In conclusion, differential pressure gauges with diaphragm seals are a testament to the crucial intersection of engineering expertise and practical application. Their role in safeguarding processes across varied industries cannot be overstated, equipping professionals with not just a tool, but a robust solution to their pressure measurement needs. By leveraging cutting-edge design, superior materials, and rigorous testing, these instruments assure precise and reliable measurement, embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness at every level of their application.

Share

Latest news

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025